Wear protection blocks on high-bay warehouses

Bottom rail storage and retrieval machine

Blocks and mountings: Standard types 0030. Adhesion blocks type 10035 for protecting rail from wear and adjustment of the optimal friction coefficient (0,6) on drive wheels.

Wear protection and dry lubrication through lubrication blocks 10036 or HG045 on lateral supporting rollers.

Various dimensions are possible!

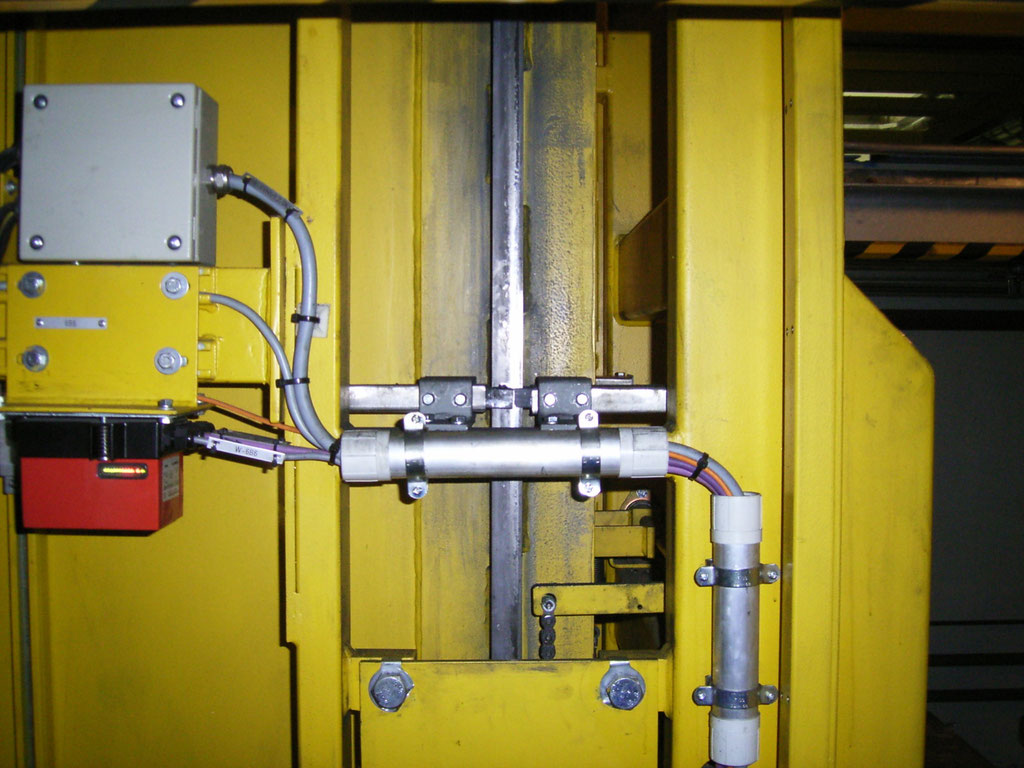

Vertical rail storage and retrieval machine

Blocks and mountings: Standard types 0020. Lubrication blocks type 10036 in case of increased wear on rolls and rails.

Lubrication blocks type HG045 for standard dry lubrication.

All dimensions are available depending on rail width!

In case of highly stressed lateral drive wheels, we suggest using lubrication blocks type 10036 – they contain more than 40% of MoS2 and generate a heavy-duty wear protection layer. Normally a thin lubrication layer from lubrication

blocks type HG045 is sufficient.

Various fixings/mountings are supplied ready-to-fit according to individual drawings or sketches.

Equipment for 1 storage and retrieval machine:

Standard set for bottom rail, consisting of:

1 x adhesion block 10035/0030 (31x55x100mm), mounting and clamping device

2 x lubrication block 10036/0030 (31x55x100mm) or

block HG045/0020

(20x45x60mm), mountings and clamping devices

Standard set for vertical rail, consisting of:

3 x lubrication block 10036/0020 or block

3 x mounting H0020, with spyhole

3 x clamping device H0020- HR